IOTEC has engineering team with extensive experience in a range of assembly solutions, from stand-alone operator assisted station to a larger, fully automated assembly line

IOTEC has engineering team with extensive experience in a range of assembly solutions, from stand-alone operator assisted station to a larger, fully automated assembly line

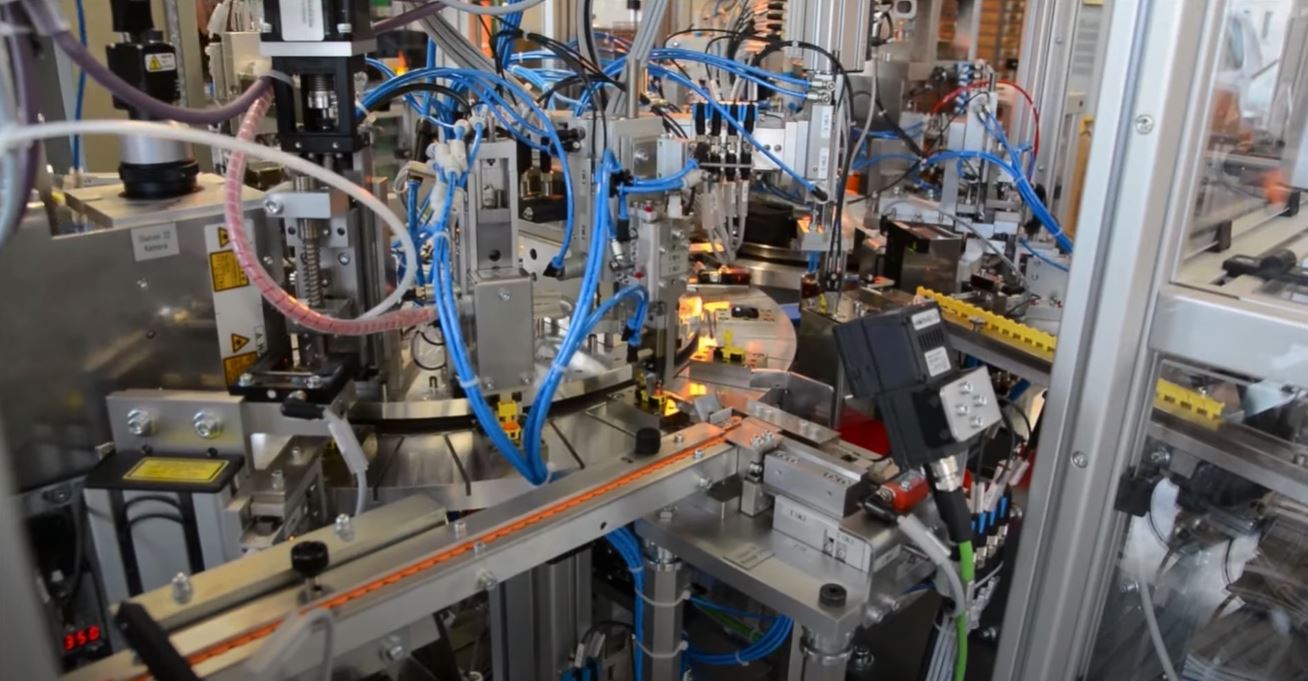

Assembly automation is the strategic integration of advanced technology within assembly processes. Typically, this advanced technology includes manipulated and or cartesian robotics, automated pneumatic hydraulics mechanism, and sensors to manipulate parts for assembly. Automated robots can be deployed and reconfigured quickly to meet high throughput goals, satisfying increased demand for high-speed and high-quality manufacturing.

For example, companies have integrated robotics into their assembly processes for injection molding, wire harness, semiconductor, automotive, aerospace, medical, heavy equipment, and consumer products. Further, industries such as consumer electronics, appliances, and medical devices require speed and precision. Automated equipment is ideal for completing the repetitive tasks of applying adhesives and sealants or accurately assembling small parts.

Whether your parts are manually loaded or fed into our system, we have the know-how assembly your components together into their final form. Our expertise includes:

IOTEC Engineering Team can build proofs of concept and integrate third-party machines, so you have the automation in places you need.

We specialize in integrating assembly and material handling automation solutions into your production process. Our solutions include feeding systems, auto cutting, injection mold robot, palletizing and depalletizing, pick-and-place solutions, and more.

IOTEC offer a full advance application development team with expertise in designing and validating custom automation solutions. Our online monitoring and commanding technology can deliver your process traceability anytime, anywhere its needed.

Advanced automation and robotics involve using cutting-edge technology or developing technology that doesn’t exist yet for manufacturing, material handling, and other industrial applications. We work with customers to develop new applications of robotics, vision, and inspection to assemble parts and products, optimize and improve distribution centers, soldering robot, and more.

Advanced applications is our team of expert engineers who specialize in prototyping, designing, and validating custom automation systems. IOTEC is passionate about developing custom solutions for our customers, so we created a dedicated team to develop and prove out solutions to unique and challenging applications to ensure that the equipment we build works the way it’s supposed to and meets our customers’ goals. The advanced applications team supports IOTEC sales, applications engineering, and business unit groups with proof-of-principle prototyping, testing, and validation in a cutting-edge engineering lab.

Consultation and education are vital to us. Many companies want to adopt custom automated manufacturing, but there are still large gaps in knowledge of when and where to integrate automation, robotics, and vision to realize high investment returns. This is where the advanced applications team steps in with consulting and educating. They also help evaluate how automation in production lines improve efficiency and quality.

We are focused on reliability improvement, new and better ways to meet our costumers’ needs. Our experienced team never stop to concept, design, build, wire, program, install and improve in nearly every Industry.

We are focused on reliability improvement, new and better ways to meet our costumers’ needs. Our experienced team never stop to concept, design, build, wire, program, install and improve in nearly every Industry.